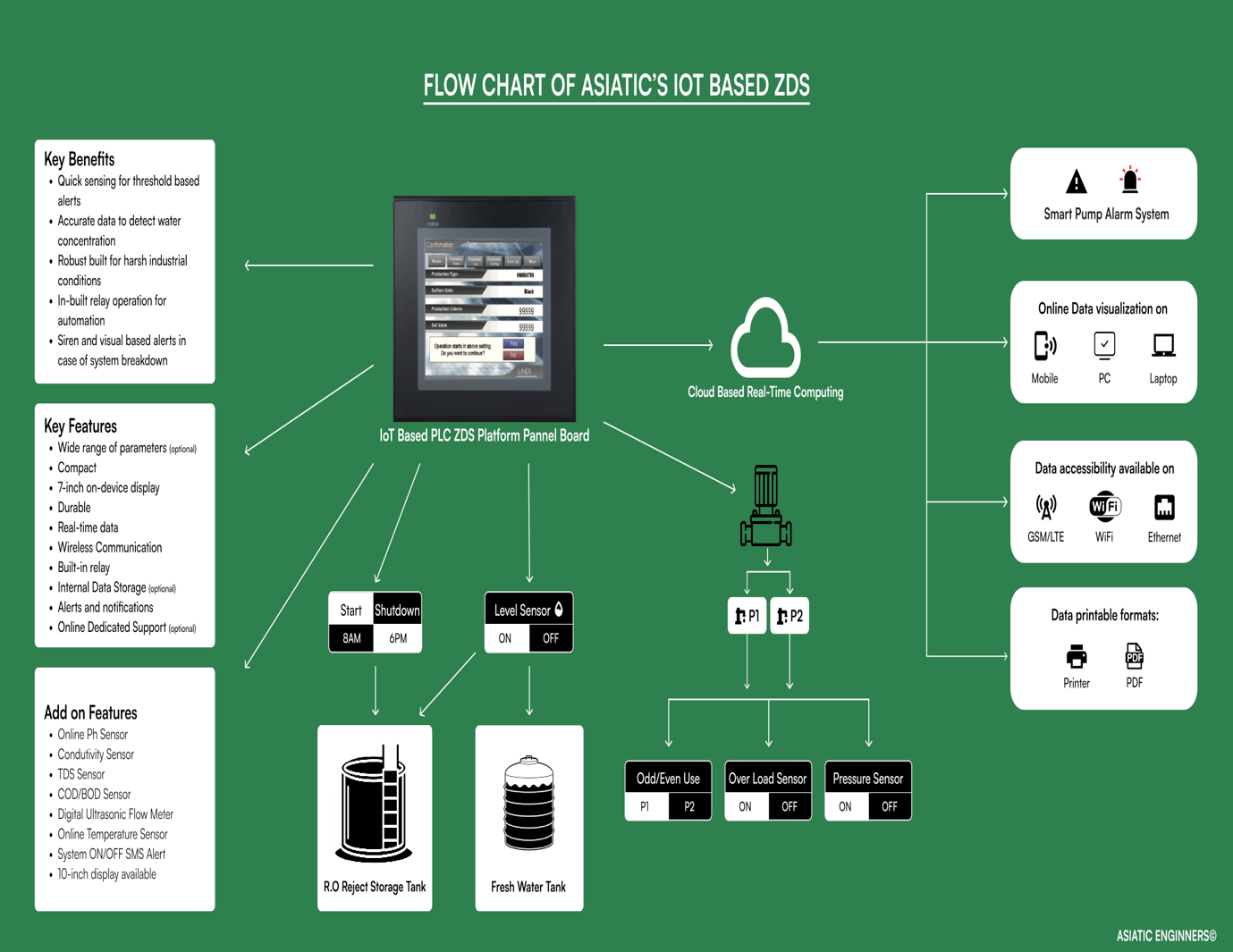

ZLD -> Zero Discharge System

What is Zero Liquid Discharge (ZLD) ?

Compliance of ‘Zero Liquid Discharge’ requirement, in which, the industry is not

supposed to discharge any effluent outside its premises is really a very tough

requirement from the techno-economic and sustainability and maintenance viewpoints.

From daily operations, industries generate large quantity of effluents ranging from

1000 liters/hr to 100,000 liters/hr depending upon the quantum of the goods

processed. Sustained, genuine and techno-economically viable ‘Zero Discharge’

compliance for many industries is extremely difficult, if they have to adopt any of

the conventional treatment for elimination of waste water such as;

- Incineration,

- Multiple Effect Evaporation,

- Solar Evaporation,

- Spray Drying and so on.

Handling of MEE / Incineration / Spray-drying (Thermal Evaporation) has become very costly and it require huge maintenance cost & labor force to run and resultant degradation of their efficiency, therefor it’s an ever-increasing problem of industries in many parts of the India and around the world.

Why Asiatic’s ZLD Non-Thermal Evaporation is Cost-Effective ?

‘Zero Discharge’ in general means that no wastes are discharged in the environment. Everything is recycled and no pollutants are let-out into the environment. It is sometimes also referred to as Totally Effluent Free. You are aware that evolution of treated waste water discharge standards is a complex process requiring thorough expertise. Zero Discharge is one such standard / requirement of pollution control authorities. In reality and over a long period, some discharges are bound to take place; unless there is an enormous storage capacity or it can be vaporized. Therefore, we often consider “Zero Discharge” as MYTH !!!

Why Asiatic’s ZLD Non-Thermal Evaporation has LOW CAPEX & LOW OPEX ?

Asiatic’s cost effective Zero or low Maintenance Zero Liquid Discharge Evaporation System for the treatment of High TDS RO Reject / Leachate by evaporating naturally without heat input. Evaporation can be achieve based on ambient weather condition like temperature, Humidity & Wind Velocity. Evaporation capacity also affect if the salt concentration in the Effluent is high or effluent specific gravity is more then one..

Benefit of Zero Liquid Discharge

- ZLD is based on Non thermal diffusional evaporation technique which doesn’t require steam or heat.

- ZLD is less maintenance system.

- ZLD require less labor force compare to MEE or other thermal evaporation system.

- ZLD has less footprint.

- ZLD CAPEX is also very less compare to MEE.

- ZLD operating cost is 200 Rs/ 1KL (2.5 $ /1000 liter) means payback period is less then 8 months.

- Equipment Replacement cost in ZLD is more then 4 years if the effluent characteristics maintain as per feed data.

ZLD OPEX Calculations against MEE / Incineration

- MEE Operating Cost : 1700 to 2000 Rs. / 1 KL or more.

- ZLD Evaporation operating cost : 180-200 Rs / 1 KL.

- OPEX SAVE [A (1700) – B (200)] : 1500 Rs saving per 1000 liter (1KL).

ZLD OPEX Saving Calculation:

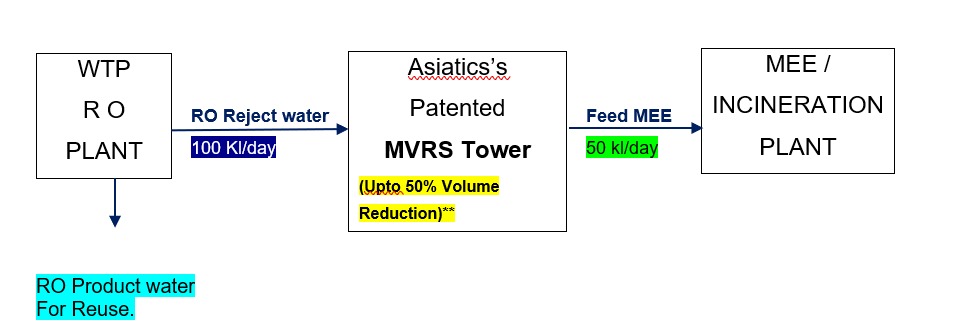

100 KL x 1500 Rs. (Saving on OPEX by using MVRS) = 75,000 Rs/day.

75,000 Rs/day x 365 days = 2.73 CR.

Payback period is less then 8 months.

Asiatics’s Patented

ZLD Tower

**evaporation rate in MVRS Tower may very upon input characteristics of RO Reject

& ambient weather condition of respective site / location.