MVRS -> HIGH TDS EVAPORATION SYSTEM

What is Zero Liquid Discharge for MVRS ?

Compliance of ‘Zero Liquid Discharge’ requirement, in which, the industry is not

supposed to discharge any effluent outside its premises is really a very tough

requirement from the techno-economic and sustainability and maintenance viewpoints.

From daily operations, industries generate large quantity of effluents ranging from

1000 liters/hr to 100,000 liters/hr depending upon the quantum of the goods

processed. Sustained, genuine and techno-economically viable ‘Zero Discharge’

compliance for many industries is extremely difficult, if they have to adopt any of

the conventional treatment for elimination of waste water such as;

- Incineration,

- Multiple Effect Evaporation,

- Solar Evaporation,

- Spray Drying and so on.

Handling of MEE / Incineration / Spray-drying (Thermal Evaporation) has become very costly and it require huge maintenance cost & labor force to run and resultant degradation of their efficiency, therefor it’s an ever-increasing problem of industries in many parts of the India and around the world.

How to reduce MEE / Incineration / Spray-drying volume & cost by MVRS (MEE Volume Reduction System) ?

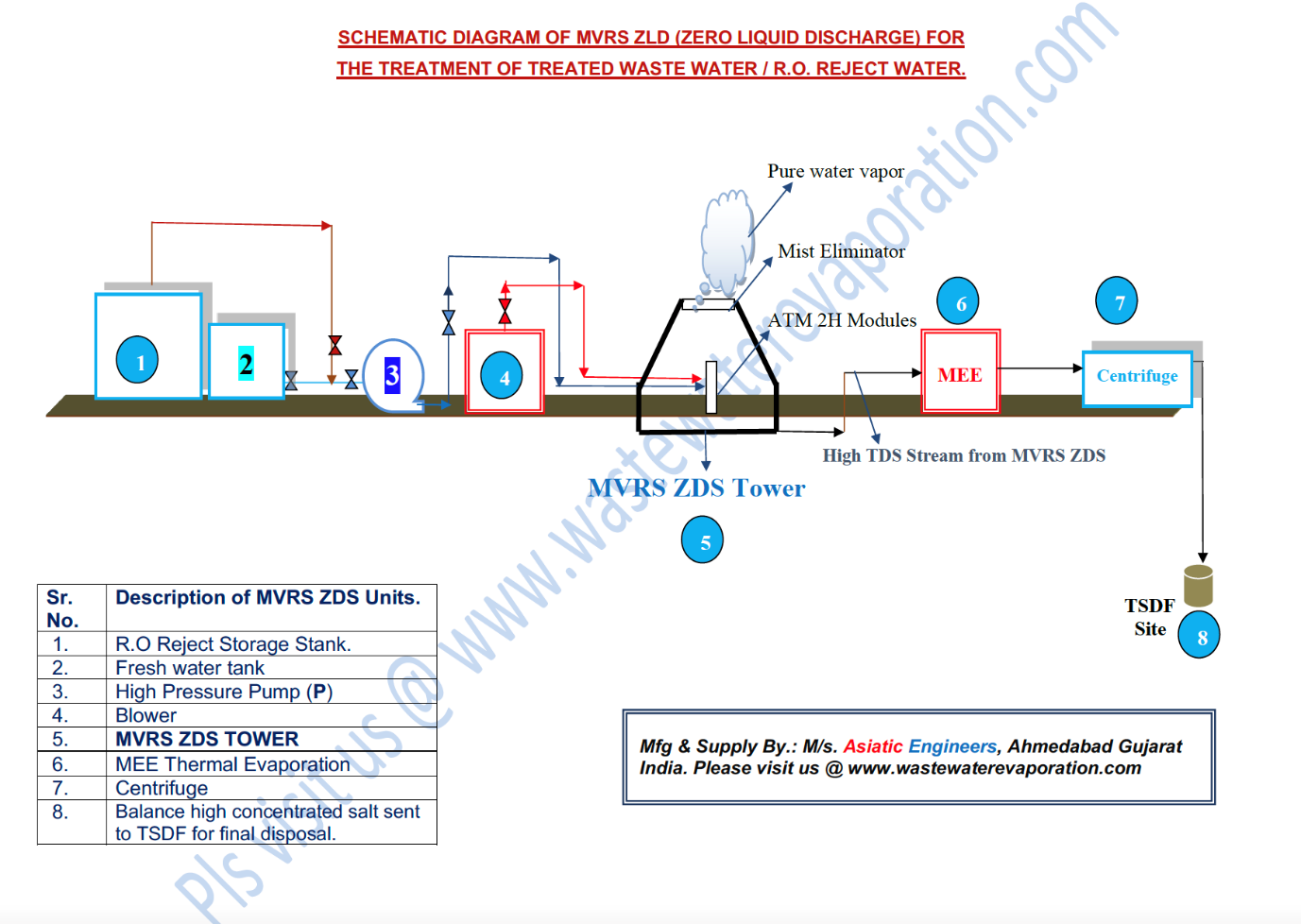

To overcome handling of MEE / Incineration / Spray-drying (Thermal Evaporation)

problem, We M/s Asiatic Engineers, Ahmedabad has come with MVRS (MEE Volume

Reduction System) which is Novel & Patented to reduce MEE / Incineration /

Spray-drying (Thermal Evaporation) Volume Reduction up to 50%** to save huge cost

over CAPEX & OPEX on such thermal evaporation.

To overcome handling of MEE / Incineration / Spray-drying (Thermal Evaporation)

problem, We M/s Asiatic Engineers, Ahmedabad has come with MVRS (MEE Volume

Reduction System) which is Novel & Patented to reduce MEE / Incineration /

Spray-drying (Thermal Evaporation) Volume Reduction up to 50%** to save huge cost

over CAPEX & OPEX on such thermal evaporation.

The Flow rate of ATM 2H Is about 15 liters / Minute which is 900 liter per hour

which means if you operate MVRS Tower for 24 hrs/day then you will get approximately

20,000 Liters in 24 hrs. Evaporation efficiency changes throughout the day as the

sun heats the air, the efficiency at night is not good because the air is more dense

and if the air is more dense then you have less the air can absorb, so your flow

rate has adjust according to atmospheric conditions.

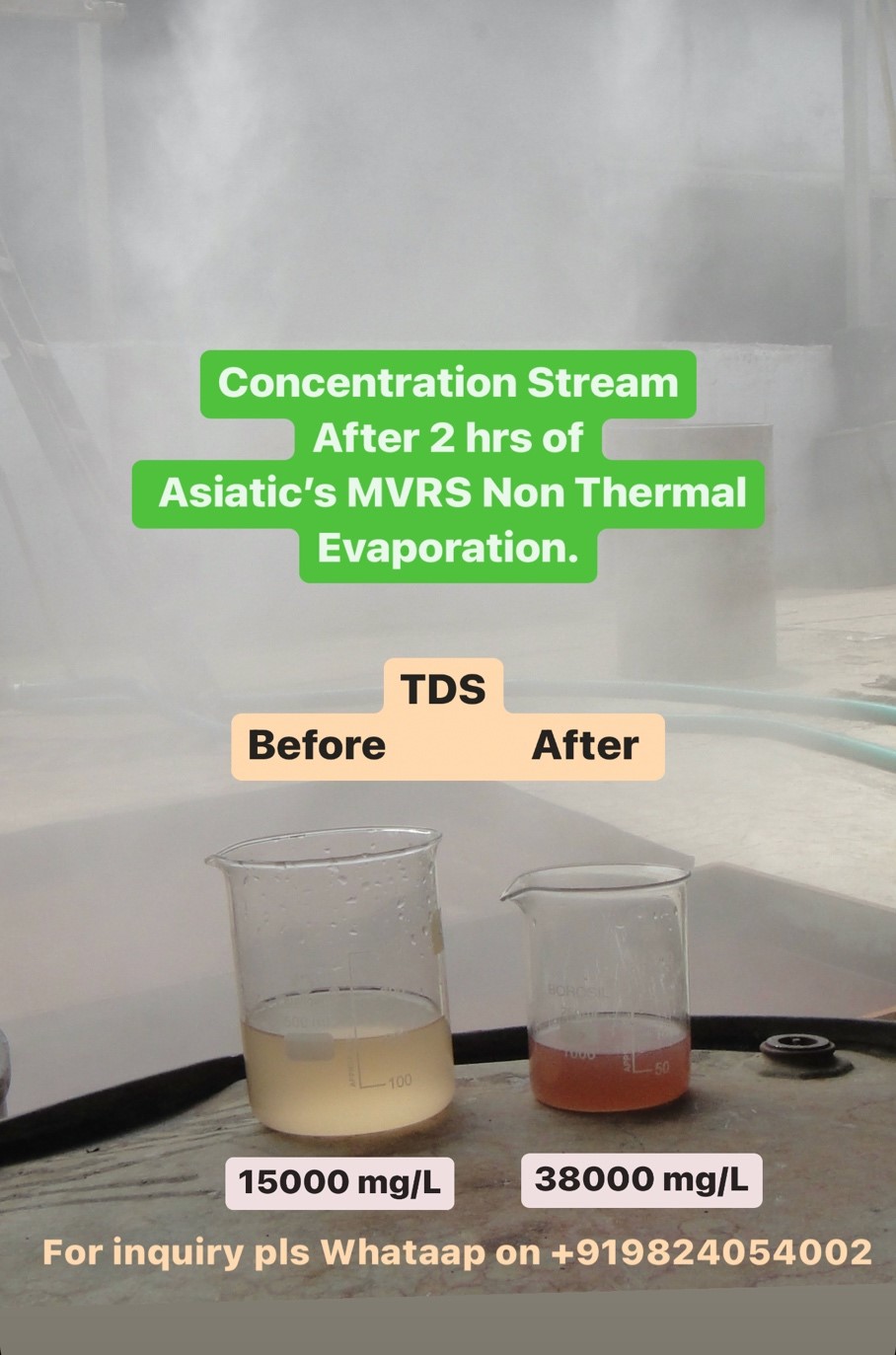

High TDS (salt) effect on MVRS evaporation ?

RO Reject water has High TDS (salt) then will have less efficiency in the MVRS Evaporation Tower. MVRS evaporation efficiency governs how much salt present in the RO Reject liquid and remaining salt water in the MVRS tower goes to the sump at the bottom of the MVRS Tower to hold the liquid coming from the RO Reject Collection tank. If we are not heating the air, it may effect on evaporation flow when air is more dense / cloudy weather. Evaporation flow also reduced during the evening or night time hours due to temperature changes in the atmosphere.

What happen to High TDS (salt) of RO Reject water ?

During our studies over the years on various high TDS RO Reject water on MVRS system, we found that salt will remain within the MVRS Tower, the physical process requires that when water as a liquid converts to a vapor, the salt particle is separated from the water, Since water vapor is lighter than air, it rises and goes out the chamber opening at the top.

Why Asiatic’s MVRS Non-Thermal Evaporation is Cost-Effective ?

‘Zero Discharge’ in general means that no wastes are discharged in the environment. Everything is recycled and no pollutants are let-out into the environment. It is sometimes also referred to as Totally Effluent Free. You are aware that evolution of treated waste water discharge standards is a complex process requiring thorough expertise. Zero Discharge is one such standard / requirement of pollution control authorities. In reality and over a long period, some discharges are bound to take place; unless there is an enormous storage capacity or it can be vaporized. Therefore, we often consider “Zero Discharge” as MYTH !!!

Why Asiatic’s MVRS Non-Thermal Evaporation has LOW CAPEX & LOW OPEX ?

Asiatic’s cost effective Zero or low Maintenance MVRS Evaporation System for Volume reduction of High TDS RO Reject / Leachate before feeding to MEE / Incineration / Spray-drying system. Volume reduction can be achieve based on ambient weather condition like temperature, Humidity & Wind Velocity. Asiatic’s MVRS volume reduction % will be in the range of 30 to 50% or more on based of Effluent / TDS Characteristics.

Benefit of MVRS Tower

- MVRS is based on Non thermal diffusional evaporation technique which doesn’t require steam or heat.

- MVRS is less maintenance system.

- MVRS require less labor force compare to MEE.

- MVRS has less footprint.

- CAPEX is also very less.

- MVRS operating cost is 300 Rs/ 1KL (3.7$ /1000 liter) means payback period is less then 8 months.

- Equipment Replacement cost in MVRS is very less.

MVRS OPEX Calculations against MEE / Incineration

- MEE Operating Cost : 1700 to 2000 Rs. / 1 KL or more.

- ZLD Evaporation operating cost : 180-200 Rs / 1 KL.

- OPEX SAVE [A (1700) – B (200)] : 1500 Rs saving per 1000 liter (1KL).

If client is feeding 100 KL / day in MEE or in Spray Dryer and by using MVRS they can reduce 50%** Volume means evaporating 50 KL / day. Therefore now client has to feed only 50 KL into MEE, instead of 100 liter/day.

MVRS OPEX Saving Calculation:

50 KL x 1500 Rs. (Saving on OPEX by using MVRS) = 75,000 Rs/day.

75,000 Rs/day x 365 days = 2.73 CR.

Payback period is less then 6 to 8 months.

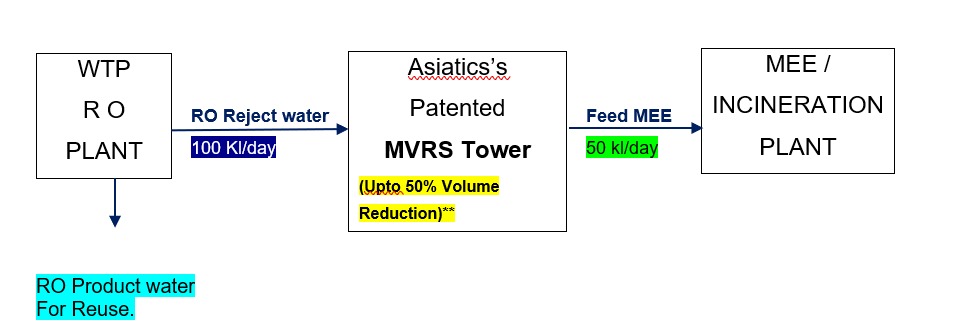

MEE / INCINERATION PLANT

Asiatics’s Patented

MVRS Tower

(Upto 50% Volume Reduction)**

WTP,

R O PLANT,

RO Reject water, Feed MEE

100 Kl/day 50 kl/day

RO Product water For Reuse.