‘Zero Liquid Discharge’ in general means that no wastes are discharged in the

environment. Everything is recycled and no pollutants are let-out into the

environment. It is sometimes also referred to as Totally Effluent Free. You are

aware that evolution of treated waste water discharge standards is a complex process

requiring thorough expertise. Zero Discharge is one such standard / requirement of

pollution control authorities. In reality and over a long period, some discharges

are bound to take place; unless there is an enormous storage capacity or it can be

vaporized. Therefore, we often consider “Zero Discharge” as MYTH !!!

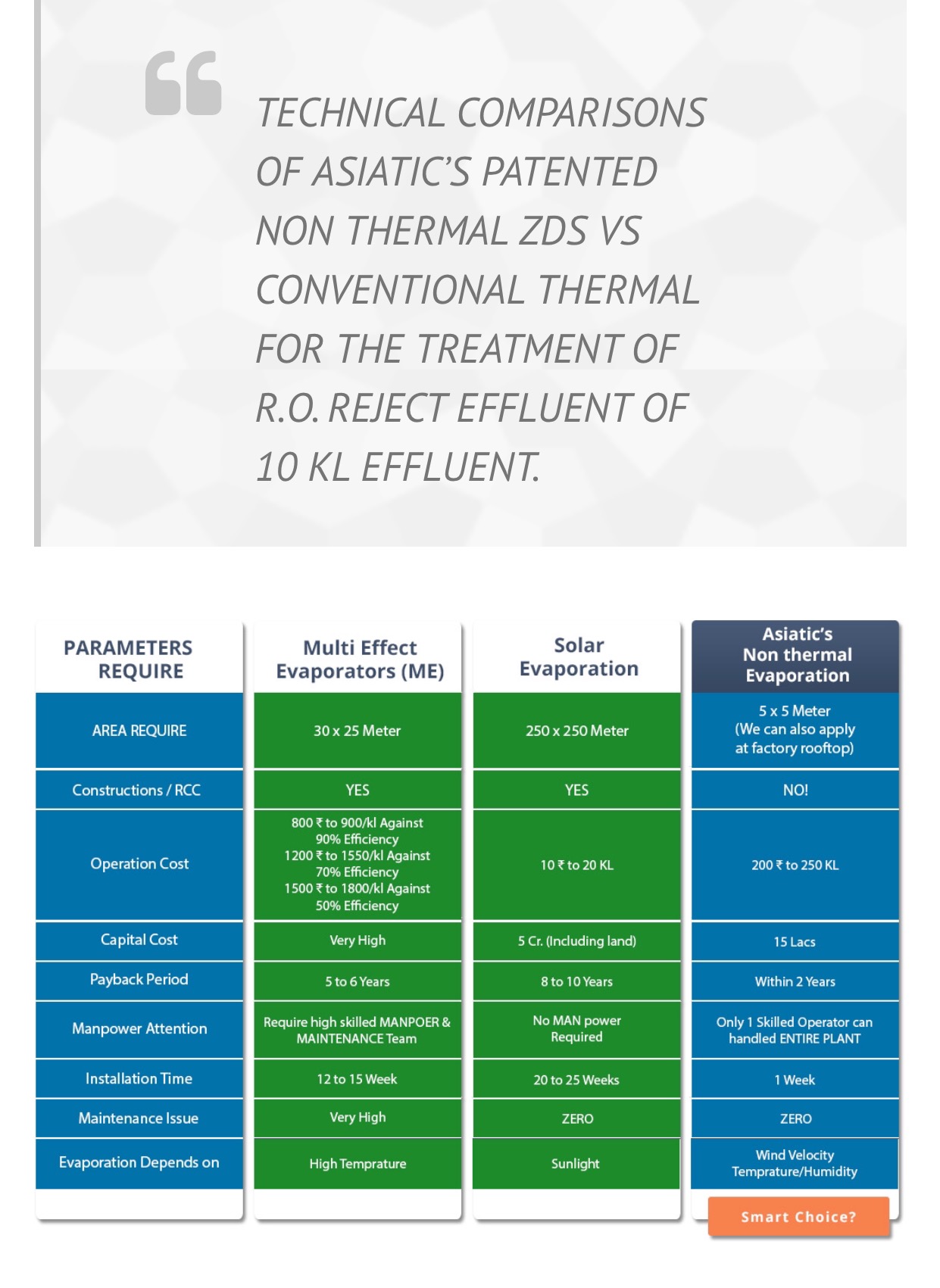

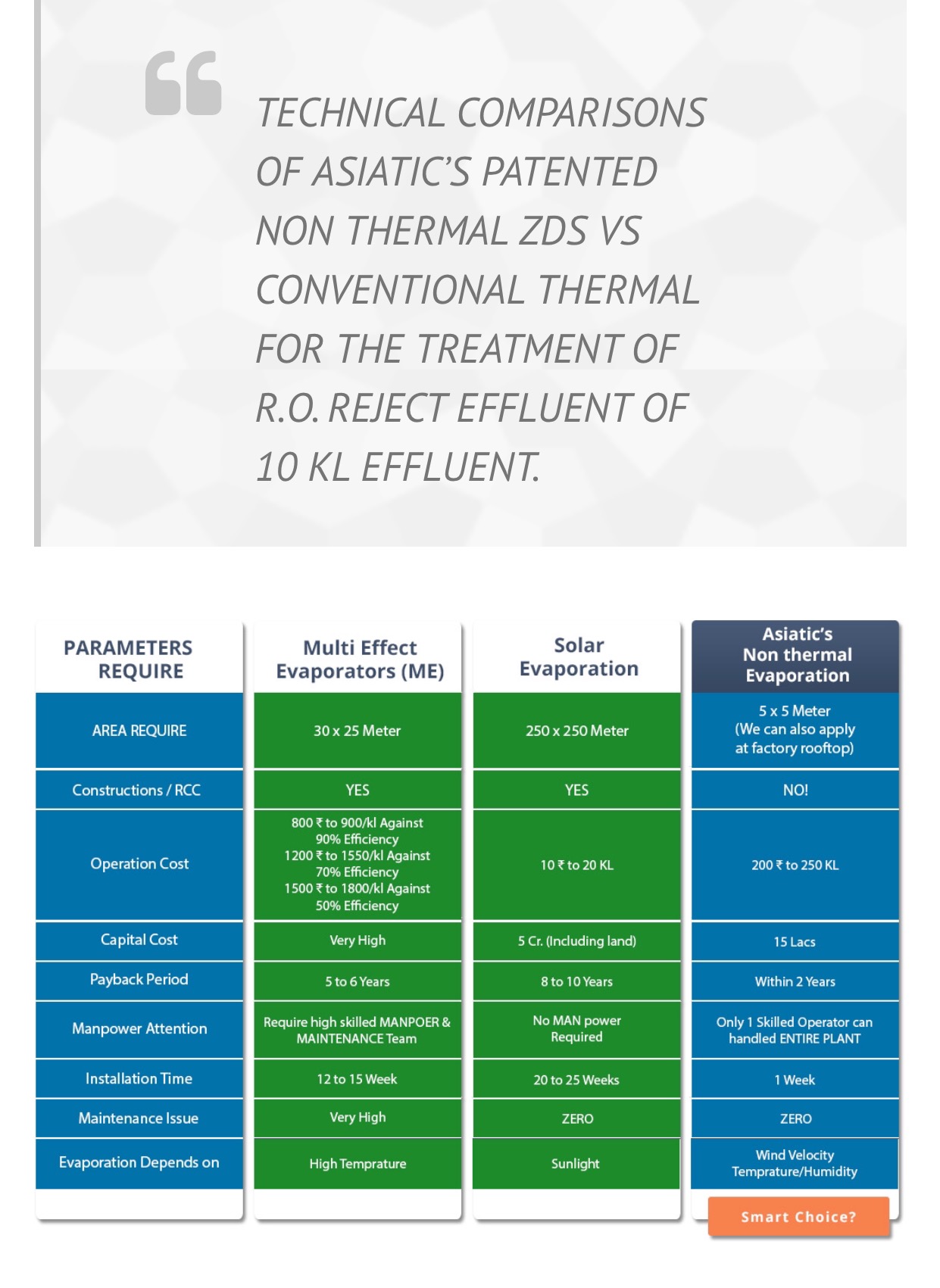

We worked on the word 'Vaporized' from above conclusion. It was also thought that in

various technological innovations, by and large the pollutants are targeted for the

treatment but here the approach is different and the main emphasis is given to the,

“Water Part” of the waste water and not the pollutants. In short treated water was

evaporated in a cost effective manner without any thermal treatment, which itself is

a unique feature of the ZDS. Only input to the system is electrical energy.

Essential Pre-requisites for ZDS

As discussed and explained, the prerequisites which the client will have to provide

are;

- Well equalized treated effluent after R.O. Reject stream

- pH of the effluent is near about neutral

- Proper VOCs removed by diffused aeration

- Proper filtration of the effluent in a suitable filter / screens so that

the effluent input to the ZDS is totally without turbidity and suspended

solids.

For further information on our Zero Discharge Technology, we request to

provide your

effluent data to our team and we will provide you our budgetary quote for

the same.

What is Vermitechnology process

(Bio-compost) ?

Bio-Conversation of organic waste is a natural biological process, carried out under

controlled conditions, which converts organic material into a stable humus-like

product called Bio-compost. During the composting process, various microorganisms,

including bacteria and fungi, break down organic material into simpler substances.

‘Bio-Composting’ is an aerobic process with the help of special type of verms in the

process to maintain oxygen level during aeration process, because the microorganisms

require oxygen to do their work.

What can be ‘Bio-Composted’?

‘Bio-Composting’ has the potential to manage all of the organic material in the waste

stream which cannot otherwise be recycled. Some examples of organic material that

can be composted include food scraps, leaves and yard wastes, agricultural crop

residues, paper products, sewage sludge and wood.

Can ‘Bio-composting’ manage all our wastes?

Since approximately 50% of the waste stream is organic matter, ‘Bio-composting’ can

play an important role in the integrated waste management plans of any community.

However, the remainder of the waste stream (such as items made of plastic, glass,

metals, ceramics and rubber) cannot be composted.

What are the benefits of a successful ‘Bio-composting’ program?

In addition to diverting a large proportion of the organic waste stream away from

disposal, an effective ‘Bio-composting’ program can produce a high quality soil

amendment with a variety of end uses. Diverting organic wastes from landfill sites

helps to conserve landfill space and to reduce the production of leach ate and

methane gas (both of which add to the cost of operating a landfill).

What steps can be taken to ensure that a facility produces high

quality ‘Bio-compost’?

The most important step in producing a high quality ‘Bio-compost’ is to control the

quality of the material entering the process. This is most often achieved through

source separation. Source-separated organics are those organic wastes which have

been separated from potential contaminants prior to collection. Other contaminants

can be removed through a pre-processing stage or by screening the final compost.

Finally, the composting process itself can determine some characteristics of the

final ‘Bio-compost’, such as maturity / physical & chemical characteristics and

particle size.

END USES FOR ‘BIO-COMPOST’

Are there markets and end uses for ‘Bio-compost’?

‘Bio-Compost’ can be used in many applications depending on the quality produced and

the quality of the product. High quality ‘Bio-compost’ is being used in agriculture,

horticulture, landscaping and home gardening. Medium quality ‘Bio-compost’ can be

used in applications such as erosion control and roadside landscaping. Even low

quality ‘Bio-compost’ can be used as a landfill cover or in land reclamation

projects.

Is ‘Bio-Compost’ a Bio-fertilizer?

‘Bio-Compost’ can contain varying amounts of nutrients such as nitrogen, phosphorus

and potassium. However, the concentrations of these nutrients in compost are usually

lower than those found in common fertilizers.

‘Bio-Compost’ is more properly described as a soil amendment or soil conditioner

which returns valuable organic material to the soil. In addition, ‘Bio-compost’ does

benefit the soil be improving soil structure, aeration and water retention. Very

Large Scale “Vermitechnology” offers an ecologically and commercially sustainable

alternative to decompose the organic waste in to Bio-Fertilizer and the major

advantages are:

- A pollution free process. It produces no odor or leach ate.

- Capable of being installed within the grounds of a treatment plant

eliminating transport of raw sludge.

- Could be used to process other organic wastes generated in the region.

- Reduction in volume with Low energy consumption.

- Small amount of operation attention and skills required.

- Increase in nutrient value of converted sludge.

- Produces a higher value by product as ‘Bio-compost (Bio-Fertilizer). This t

is of course 100% organic and can be 5-11 times more powerful than chemical

fertilizer.

Thus the treatment methods for solid waste are used to reduce the mass or volume and

to achieve one or more of the following objective :

- Reduction in volume of required land for filing solid waste.

- Improvement of its acceptability in the terms of ‘Environmental awareness’

in common people.

- Reduction in the transport cost.

- Minimization of overall cost.

For Industrial Application :

- Textile Solid Waste.

- Dairy Solid waste.

- Municipal Solid Waste.

- Pharmaceuticals Solid Waste.

- Canteen Waste.

Benefits

Increase in the nutrient value as By product of such process :

[A] In the process of ‘Bio-composting’ the earthworm release other minerals like Ca,

MG, K, N, P, and increase the nutrient value of converted Organic Sludge.

[B] The University of Florida ran an analysis of a soil from an earthworm bed giving

the following results. The values are the total amounts present in the converted

sludge.

Percentages of Nitrogen, Phosphorus and Potassium in converted sludge.

Nitrogen (N) 1.74%

Phosphorus (P) 0.67%